WITH 3D-PRINTED AIRPLANES becoming more popular, there are now many Facebook groups and online forums that discuss this topic. I have read about a common error that occurs, especially to those who are new to 3D printing, in regard to lightweight polylactic acid (LW-PLA) filament.

There are two kinds of LW-PLA filament: active-foaming and "pre-foamed." The error that occurs most often is that people buy pre-foamed LW-PLA and try to use it on a design that is intended for active-foaming LW-PLW, which results in the airplane printing severely overweight—and it might not even fly at all. Additionally, if stock G-codes are used with the incorrect material, the print will appear under-extruded or possibly fail to print because the filament is not foaming when it’s printed.

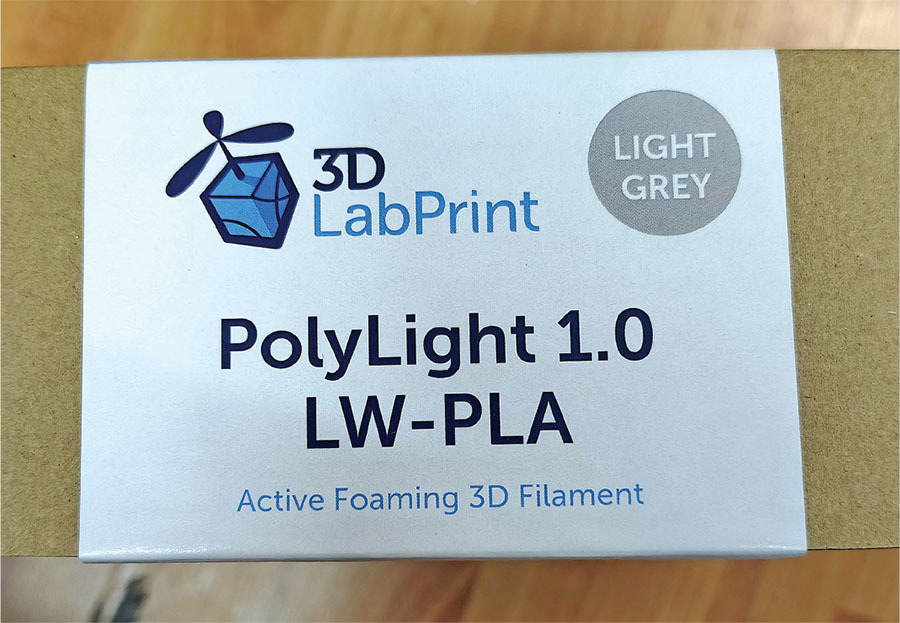

This mistake is easily made because the names of the products are very similar. Those who are not familiar with the two types can easily assume that all LW-PLA filament is the same. Polymaker sells Polylite LW-PLA, which is a pre-foamed product. 3DLabPrint sells a product called Polylight, which is an active-foaming product. With such similar names, it is easy to see why people get the two types mixed up. In fact, it can get even more confusing because Polymaker uses the term "Polylite" for other filaments, such as acrylonitrile styrene acrylate (ASA) and acrylonitrile butadiene styrene (ABS), so care is needed before ordering to make sure that you are getting the correct material.

Pre-foamed LW-PLA is manufactured in a way so that the filament is approximately 20% to 30% less dense than normal PLA. The benefit of this filament is that it typically uses the exact same print settings as regular PLA, so all you have to do is load a roll of it and print a part for an instant 20% to 30% weight savings. In the earlier days of 3D-printed airplanes, this was the easiest way to save weight.

Models are now being designed for active-foaming LW-PLA. Active-foaming means that when it prints, the filament expands as it exits out the nozzle. The hotter the nozzle temperature, the more it expands as it comes out. Because it expands, airplanes printed with an active-foaming filament typically have a nozzle flow rate that is about half the flow rate of non-foaming filament. This foaming filament results in a lighter-weight structure and a reduced airframe weight. Because of this, it has become a very popular choice for designers of 3D-printed airplanes.

Since both types of LW-PLA filaments are sold, you have to make sure that you are buying the correct type. In general, if a design lists LW-PLA, it is most likely active-foaming. Another way to tell is to look at the print profiles that the designer gives to you. The flow rate (extrusion multiplier) for active-foaming LW-PLA is typically around 0.48 to 0.56, while pre-foamed LW-PLA will have a flow rate similar to regular PLA, which is approximately 0.98 to 1.02.

As further verification, look at the printing temperature in the print profile. Active-foaming needs 240° to 260° C, while pre-foamed needs close to 200° C. Knowing the difference between these two can save you from a lot of frustration.

I am currently in the process of printing a C-17 for twin 50mm EDFs, and the design calls for active-foaming LW-PLA. I have seen some people posting photos of their C-17 parts that are significantly heavier than expected because they bought pre-foamed material by mistake. On a larger model, the weight difference really can add up and you end up with an overweight and underpowered model.

Update on the Rutan Long-EZ

The Rutan Long-EZ build that I covered in my April 2025 column was one of my most well-received builds based on the reader feedback. Since the initial column was published, I have flown the Long-EZ multiple times. I do have one small suggestion for those who have built one though.

I noticed that the model tends to climb when power is added. This was an indicator that it needed a thrustline adjustment in the motor mount, so I added a few spacer washers under the motor mount to give it a little upthrust and the behavior improved significantly. Because it is a pusher, it is technically called upthrust, but the effect is the same as adding downthrust on a tractor-mounted motor. The new thrustline angle helps push the nose down a little when power is applied. If you find that your Long-EZ model is climbing a bit too much when you add throttle, you can try adding in a few shims to adjust the thrustline.

Another change I made to the Long-EZ was to add a small carbon-fiber spar to the underside of the wing halves. I noticed that if I was flying on a windy day, the wing was flexing a little toward the tips. If I print a new version, I might up the infill ratio a few percentages to add some additional stiffness. For my quick fix, I used a 3 × 0.5mm carbon-fiber strip on the underside of each wing half and secured it with medium CA glue. This helped with the wing flexing issues.

While on the topic of carbon fiber, for several years, I have been buying my carbon-fiber strips and rods from Wind Catcher RC. The company has a wide selection of strips and rods for reasonable prices and shipping. It also carries two of the servos that I use the most on my 3D-printed airplanes: the 4.3-gram Emax ES9051 and the 8.5-gram Emax ES08A. I have used both of these servos for a few years; they have good centering and torque and do not cost a lot.

Comments

Add new comment