Goals

The following is a list of qualities, as I currently understand the problem, of a good launch dolly:

- The dolly featured weighs only 410 grams. It would weigh 470 grams with commonly available single-corrugated cardboard.

- A lightweight foam board cradle covered with foam pipe insulation.

- Tape over the front post to allow for easy liftoff. (One previous design carried a dolly into the air!)

- Mass (See #1).

- A long wheelbase to limit fore and aft rocking over rough areas.

- Stiffness to avoid bouncing around, which I don’t imagine is good for aerodynamics.

- Strength to resist ground events.

- A non-brittle structure. Beams of spruce or basswood flanges with corrugated cardboard shear webs can take a remarkable amount of abuse.

- A low profile to reduce fore and aft rocking.

Having smooth, uneventful takeoffs of our RC airplanes is a pleasure; however, some of us find landing gear to be a pain! They add weight and complexity, as well as add to the number of things that can break.

Using a dolly or jettisonable wheels are certainly not new ideas. Usually, with some design planning and a grass landing area, an airplane without wheels can land uneventfully.

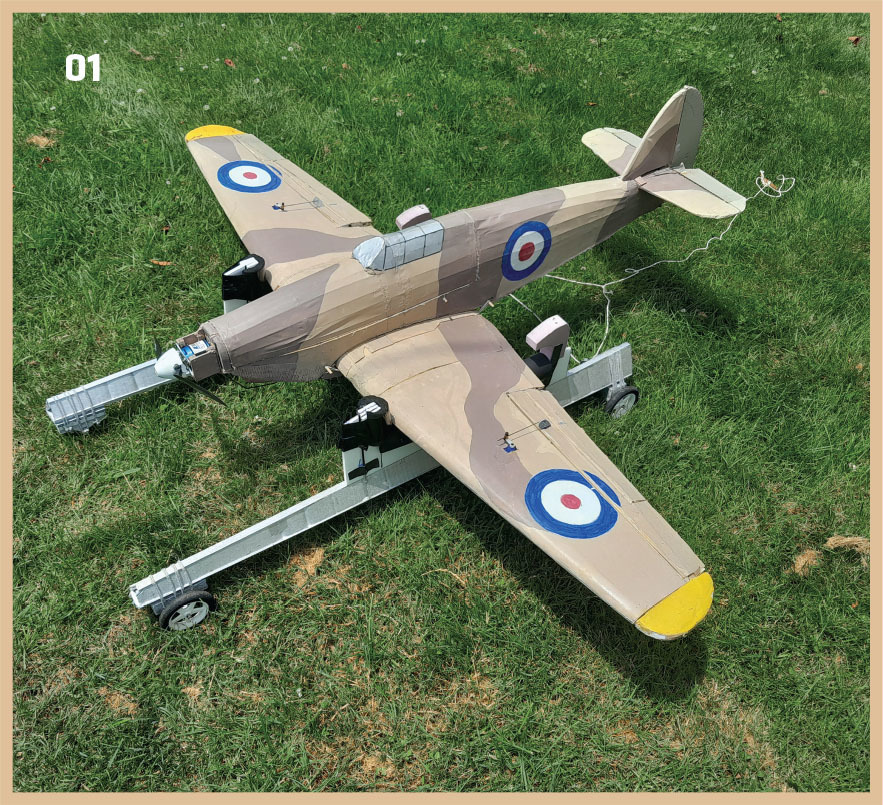

I have been scratch-building RC models from original plans on and off for 40 years and recently resolved to make a launch dolly. It was primarily for an A-4 ducted-fan model, but it would also help with wheelless propeller airplanes that are too big for reliable hand launching.

Early experiments with my friend, Mel Stettler, were fun and informative. One of the early findings was that weight was very important because the model’s motor now must accelerate an additional object. It is easy to make a dolly that has a similar or greater weight than a model. Mel helped diagnose some bad behavior of a previous dolly design.

Specifications/Materials Needed

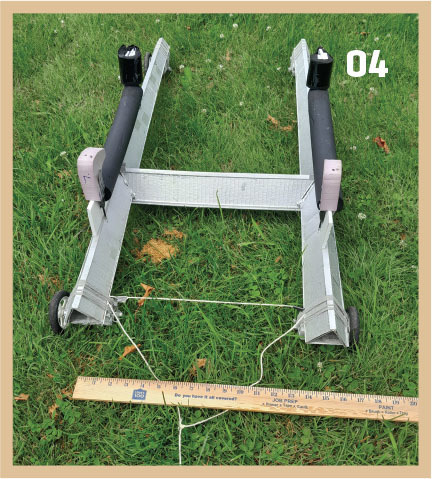

Length:36 inches

Width:18 inches

Spar flange material:1/16 × 1-cm basswood

Shear webs in spars:Lightweight corrugated cardboard of 0.31 grams per sq. in. Most single-layer corrugated cardboard weighs between 0.41 and 0.45 grams per sq. in. Using more commonly available cardboard would add roughly 60 grams to the weight.

Cardboard dimensions:The pieces taper from 2-1/4 inch in the rear to 1-1/4 inch in the front. Pieces are cut with a 60° angle to allow for a flat spot at the triangle corners to accept the basswood strips.

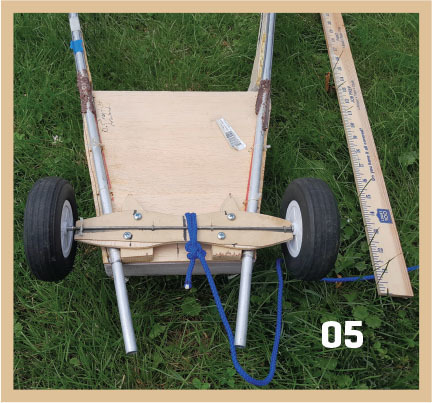

Wheels:Thin, 3-inch wheels weighing only 8 grams each.

Axles:Short 1/16-inch music wire

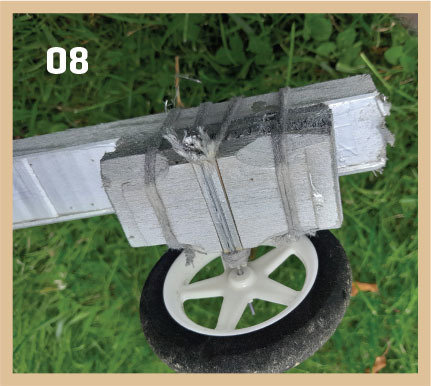

Wheel extender blocks are used to increase ground clearance:A four-ply stack is made from four layers of low-density balsa and tied to the spars with cotton string. Then, 1/8-inch balsa is added to the block to create a wide notch for an axle shaft. Knots are secured with CA.

Joining:Titebond glue is a great match made for end-grain corrugated cardboard to wood. It is used generously in forming the spars. Where flanges cross, they are sewn together with Dacron (backing) fishing line. The type of line is probably not important, but the thickness of backing line makes it easier to work with. Knots are secured with CA. Thrust posts of 3 × 2mm carbon-fiber tubing straddling the flanges are secured with CA and go to a balsa support plate on the underside of the spar (a two-ply piece of 1/16-inch balsa, partially doubled).

Axles:1/16-inch music wire is tied with outdoor upholstery thread to 1/8 × 1/4-inch spruce, with the spruce held into a notch in the bottom of the extender block.

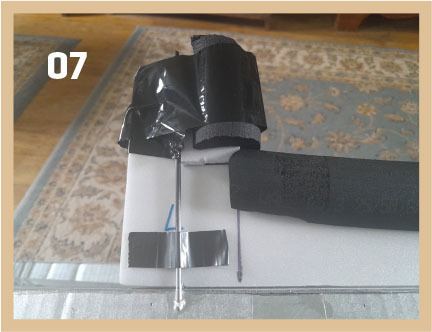

Cradle:6mm Depron foam board with 1.5-inch foam-rubber pipe insulation. The thrust area is further covered with slick tape.

Thrust rods:3mm carbon-fiber tubes allow the cradle to be flimsy since it only has to support the weight of launching airplanes. The vertical part of the cradle transfers thrust to the rods. Trailing edge (TE) hold-downs are only used for a ducted-fan A-4 jet. They are cut from 1-inch pink Styrofoam and skewered 1/8-inch pilot holes onto the carbon-fiber rods.

Paint:The Wishbone is protected from wet grass with the solvent-borne Rust-Oleum Bright Coat silver metallic. Solvent-borne paints work better than water-borne paints over cardboard. Water-borne paints will wet the cardboard and wrinkle it following corrugation lines.

This article describes one design, the Wishbone, that appears to work well as a launch dolly. It is built in an H pattern using triangular spars made from basswood and corrugated cardboard. Triangular spars, such as the ones shown here, have shown excellent strength and stiffness related to their weight.

Airplanes built around a triangular spar such as these make a nice "thunk" sound in the unlikely event that it hits a tree—or so I am told. They do not make the "crack" sound of breaking balsa that some of us might have heard.

For propeller clearance, the design chooses a wide stance and a low profile rather than a high profile with a propeller hanging out over the front.

Results and Discussion

The Wishbone works well and provides uneventful takeoffs. With a propeller-driven model, the aircraft tips downward and needs full up-elevator until it gets moving faster. Holding the path straight with rudder will soon result in liftoff. The aircraft will ride up the stationary upright, which is why it is important to use slick tape. A structure similar to the Wishbone is recommended for launching wheelless RC models.

In earlier designs, I mistakenly thought that a dolly would take care of everything! I tried full throttle right away and had cradles for each airplane to hold the TE down. I intuitively (and wrongly) imagined it going straight. I often had big veers to the side and ugly ballooning up to the sky, followed by something bad. One time, with a previous dolly, the airplane picked the poor dolly up and dropped it unceremoniously back to the ground from roughly 20 feet.

I realized that I had to practice skills similar to tail-dragger takeoffs and techniques when using the dolly. I found it best to start the takeoff run with full up-elevator in the propwash, and then to increase throttle just enough to get started. If it’s in grass, you might have to nudge it forward. Using full elevator is, of course, to prevent too much nose-down tilt.

After it begins moving, apply more throttle to gently accelerate as you ease up on the elevator. Apply rudder input as needed to keep it straight. I treat the elevator the way I do with a tail-dragger—using just enough to take off without ballooning. Ultimately, the amount of attention and skill using the Wishbone is no harder than launching a tail-dragger, but it’s not easier either!

Comments

Add new comment