When most pilots think of building a model aircraft, balsa comes to mind. Foam is becoming a very popular building material of choice. Like balsa, foam is very affordable and easy to use. On November 12, 2015, we talked with Keith Sparks about how to build with foam. Listen to the podcast below.

Recorded Podcast

Building With Foam

By Keith “Sparky” Sparks — parkflyerplastics@att.net

Photos by the author

As seen in the October 2015 issue of Model Aviation

There are three types of foam construction: slab construction, sectional construction, and panel construction. In this edition of my three-part series on foam-building techniques, I address shaping sheet foam, which I refer to in my book, Building with Foam, as panel construction because there are several types of foam sheets.

Sheet foam is extruded styrene foam and is commonly called Depron or fan-fold foam. It is manufactured in several thicknesses and densities. Because of volumetric shipping charges, ordering more than you need could actually save money.

Poster board found in department stores can also be used, but requires soaking to remove the paper and is usually lower quality. Fan-fold foam—1/4-inch blue insulation foam folded in long lengths—can be found at home improvement stores.

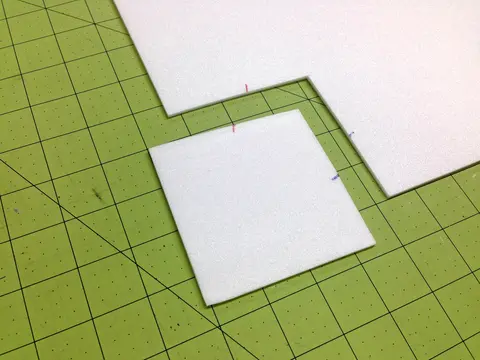

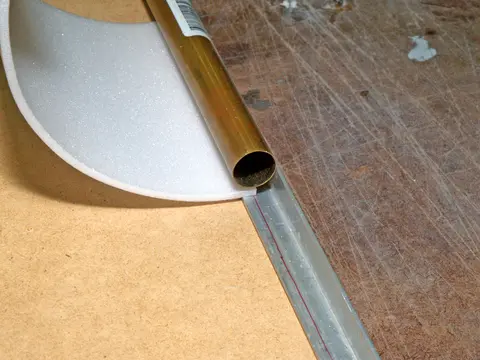

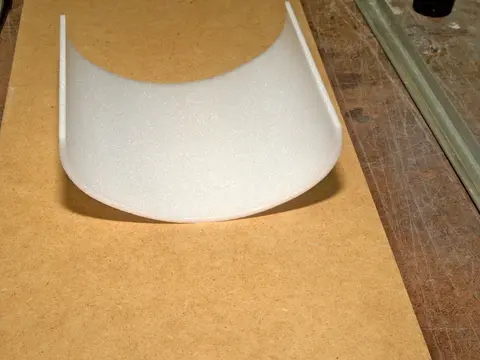

Extruded foam sheets have a grain based on the extrusion direction. Cut a corner sample and bend it over tubing in two directions. The correct direction produces a smoother inside curve. Mark the grain direction before cutting parts.

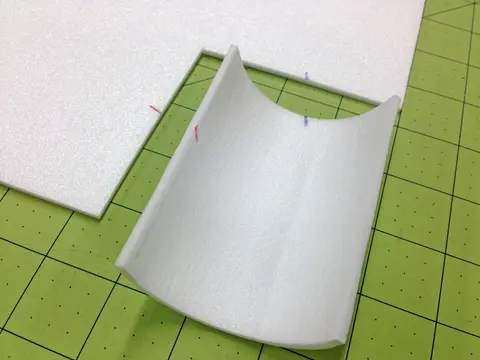

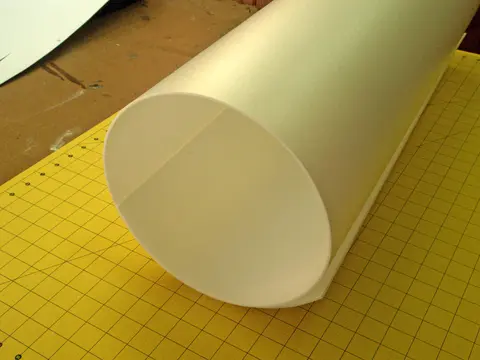

Tubing of various radii (PVC, conduit, paper tubes) can shape foam. Form tight radii gradually with progressively smaller tubes. Foam has “memory” and will spring back, so allow for this when fitting parts.

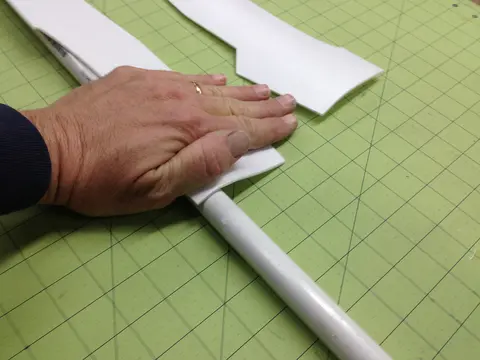

For small panels, roll tubing over the foam using palm pressure. For long panels, use angled aluminum to hold the edge and apply even pressure. Larger sheets may be rolled and held for one or two days to “cold form.”

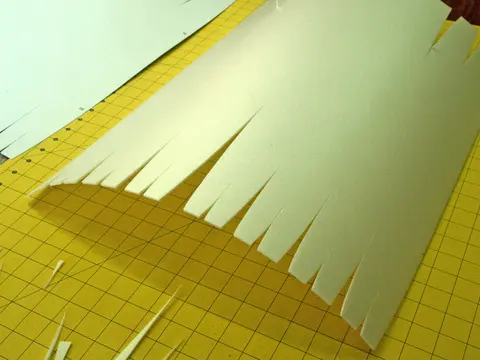

Compound curves are difficult to form. Using heat or boiling water is risky. A safer method is cutting pleats and drawing them together, similar to textile construction. This method was used to create the F-86 Cartoon Scale model.

This F-86 was made using 3mm Depron foam. The nose and tail were tapered using pleats to form compound curves. Keep plenty of sheet foam on hand to experiment, improve, and learn. —Keith Sparks

parkflyerplastics@att.net

Determining grain direction

A small sample is needed to find the grain direction. Wrinkles or imperfections may appear when bent incorrectly. Record the correct grain direction to save material.

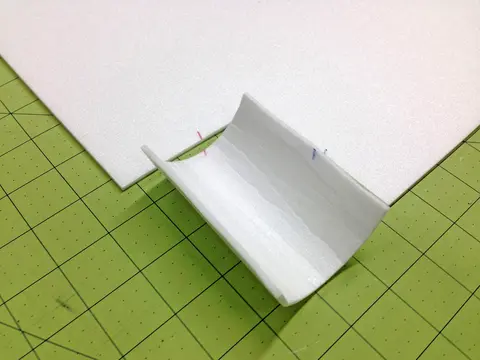

Grasping the edge

To grasp the edge of the foam sheet, use a tube and angled stock to apply even pressure. When learning, place the foam fully into the angled stock before forming.

Cold forming

Rolling sheet foam into a tight tube and letting it sit for one or two days will cold form the material, making fuselage construction easier.

Compound curves

Cutting pleats in sheet foam may be the best method for forming compound curves. Though time-consuming, it results in a lightweight fuselage.

Mind your fingers

Use only the palm of your hand when shaping foam this way. Be cautious with rings to avoid dents or damage.

Vacuum-forming

A discussion at Fantastic Models provided insight into vacuum-forming sheet foam. The process is precise and labor-intensive.

Sources:

Park Flyer Plastics

parkflyerplastics@att.net

www.parkflyerplastics.com

Comments

Add new comment