“Control Line Speed”

By Gene Hempel

As seen in the May 1988 and July 1988 Model Aviations.

Dyna-Jet history will be the subject of this month’s column. Gerald L (“Jerry”) Wiles has graciously taken the task of writing an abridged history of this remarkable powerplant for all modelers to enjoy. I have been asked many times how and who developed the Dyna-Jet engine.

“At long last, enclosed is my account of some of the history of the Dyna-Jet engine. Also enclosed are a few pictures and descriptions pertinent to that account, selected and copied from the many 8 x 10 originals loaned to me by Bill Tenney and Jerry Nolin … Though Bill and Jerry checked my narrative for accuracy, the words and opinions are, for the most part, my own.”

The Dyna-Jet and Its Manufacturers: An Abridged History

“When William L. Tenney (WLT) formed the Aeromarine Company in 1945, his main purpose was to develop two-cycle engines of an advanced design. Charles B. Marks was his first employee, a cheerful, free-spirited man of many talents and a very casual outlook. Largely self-taught, Charlie performed many tasks at the company, including those of engineer, machinist, mechanic, draftsman, and others within his wide range of skills and interests. Not incidentally, he was also extremely inquisitive.

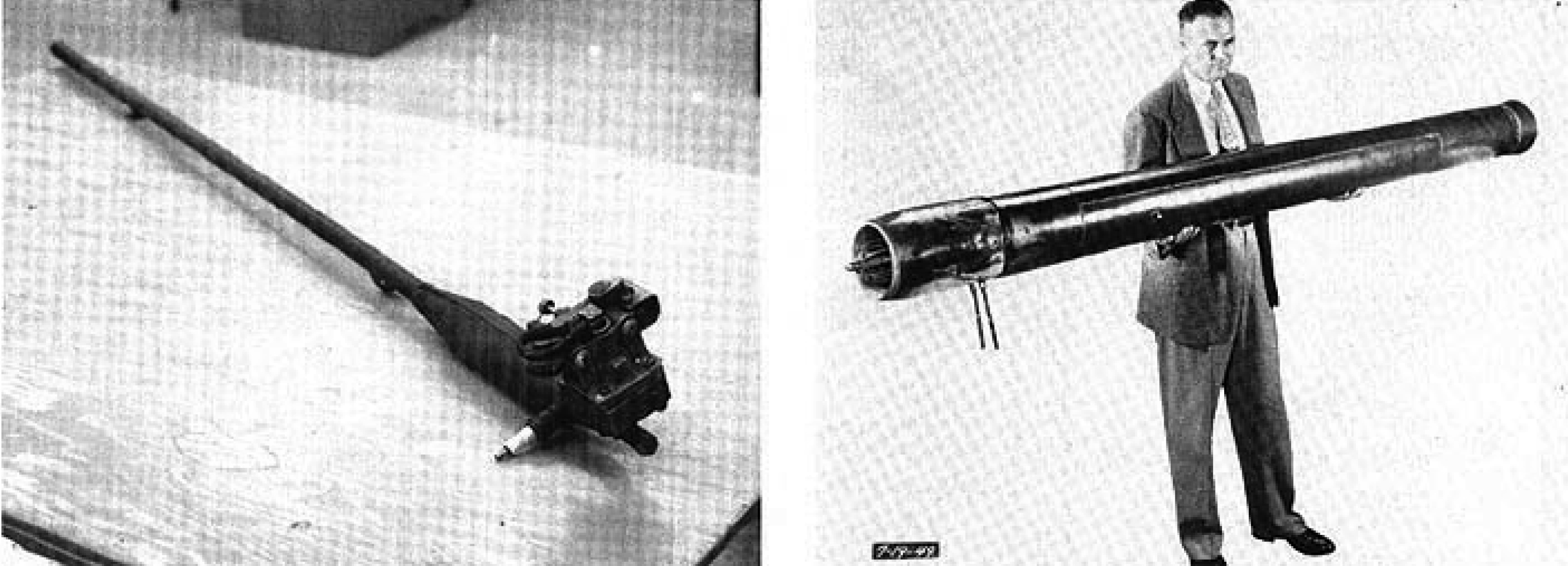

“The last-named trait led Charlie to sidetrack his primary assignments in favor of a new curiosity. He became intrigued by the very audible tests of a pulsejet engine from a German V-1 ‘Buzz Bomb’ being conducted at Wright Field, across the road from Aeromarine. By the time Bill was fully aware that the two-cycle engine work was being neglected, Charlie had put together a small pulsejet of his own design. Made of machined parts, a shell casing, and plumbing pipe and fittings, Bill’s later comment indicated his mixed emotions: ‘Unfortunately, it ran.’

“They made several versions, including some which incorporated double-edged razor blades as valve reeds. Though most could be made to run, power and reliability were usually lacking. With the advent of the Minijet and its increasingly obvious limitations, specific requirements were established for the Aeromarine’s design. Amont others, it was to be simpler to make and operate, and lower-priced than the Minijet. The final design exceeded most goals. It was first marketed in 1946 as the Dyna-Jet.

“Bill (WLT) planned to return to his boyhood home near Minneapolis once he was released from the Army Air Corps. In preparation for that transfer, he moved Aeromarine’s official mailing address to that city for a time in 1946. Changing his mind, Bill moved his company from his residence at ‘Harshman House’ near Dayton to the municipal airport at Vandalia, OH. There he shared a small building with Don Davis’ Unidev Corporation. Later occupying the entire building, Aeromarine remained there until its shutdown in late 1952.

“A close friend of Charlie’s was hired to help develop the tooling necessary for subcontractors to use in producing Dyna-Jet parts. Like Charlie and many other Aeromarine people later, Scoville Knox had many skills and interests beyond his trade of toolmaker. Among other contributions, he worked out the system for draw-forming the combustion chamber/tailpipe from 321 corrosion-resistant sheet steel.

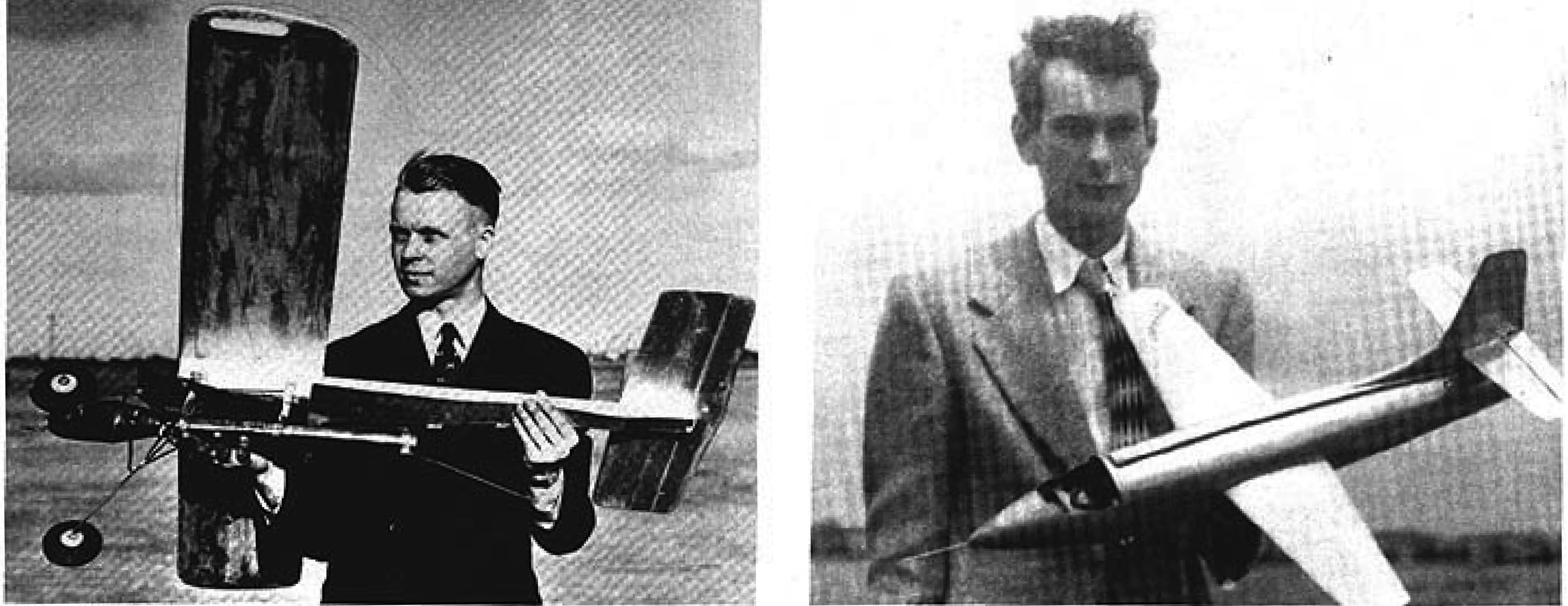

“Other skilled people were hired to aid in manufacturing the new engine, but there were no true modelers among them until G.R. (‘Jerry’) Nolin came in 1947. A WW II Mustang pilot, Jerry was a Free Flight enthusiast of longstanding who interests soon included Control Liners. (Today, he holds the AMA Duration record for Indoor Category IV Easy B Open competition). Joe Fallo, then employed at the nearby U.S. Air Force Museum, designed and built many Dyna-Jet-powered models for Jerry and others to demonstrate at contests. Plans for Joe’s Speedster were included in each new Dyna-Jet package.

“Once the engine was marketed and became nationally known, a few model kits designed for Dyna-Jet power were produced by several companies. Like today, most were commercial versions of scratch-built private designs. One of the first and most successful was Harold Bunting’s Hell-to-Hold, put out by Berkeley as their Squirt. One Stunt model was produced, along with a few Scale and sport types. Although it is known that others were planned, there seem to have been no more than 10 models actually kitted which were suitable for the Dyna-Jet—including those from foreign manufacturers.

“Charlie (Marks) left Aeromarine to return to the petroleum business, but improvements in the Dyna-Jet continued. Scovy (Knox) applied ideas of both Charlie’s and his own to increase power by almost 30% without significant increases in production costs. Labelled the Red Head, most of these engines developed 4-1/2 pounds of thrust; however, ‘fine-tuning’ would usually bring the rest to this level. To control costs, however, Jerry’s suggestion was accepted that the power be advertised as 4-1/4 pounds, since virtually all engines reached this thrust without individual adjustments.

“In 1948, Glenn Temte and Bob Thor created a sophisticated Jet Speed model which set a longstanding official AMA record of 179-plus mph! Unfortunately, both previous and subsequent flight of this, their sixth in a series of similar designs, did not attain such speeds. Consequently, many in the hobby suspected mistiming of the record flight. What makes the speed especially surprising is the realization that today’s exotic fuels and extensive engine modifications were not used (or known) at that time.

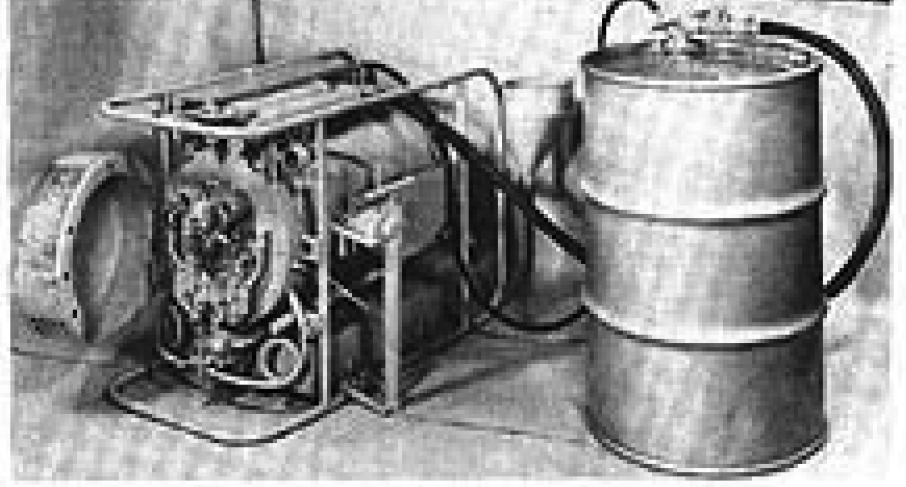

“The Dyna-Jet and its very low (for the time) fuel consumption aroused Air Force interest. One result was the development of a 35-pound-thrust engine which utilized five modified Dyna-Jet valve heads in a 7-inch-diameter, 4-foot-long design. Also investigated was the very high heat output of small pulsejets. In consequence, Aeromarine received several contracts to develop portable, ground-based preheaters for air-cooled aircraft engines at 60° below zero. (Today’s Lennox Pulse-Air furnace system uses the same principle.) One such heater used a modified Hornet model engine magneto to supply its starting spark.

“Other projects involved from one or two of an item, to several dozen, to full production quantities, in addition to the ongoing output of Dyna-Jets. Several engines measuring 8 inches in diameter and 8 feet long were made for a U.S. Navy target missile, and a smaller, dual-tailpipe version was developed. The latter was intended for powering the lift motor of a small helicopter.

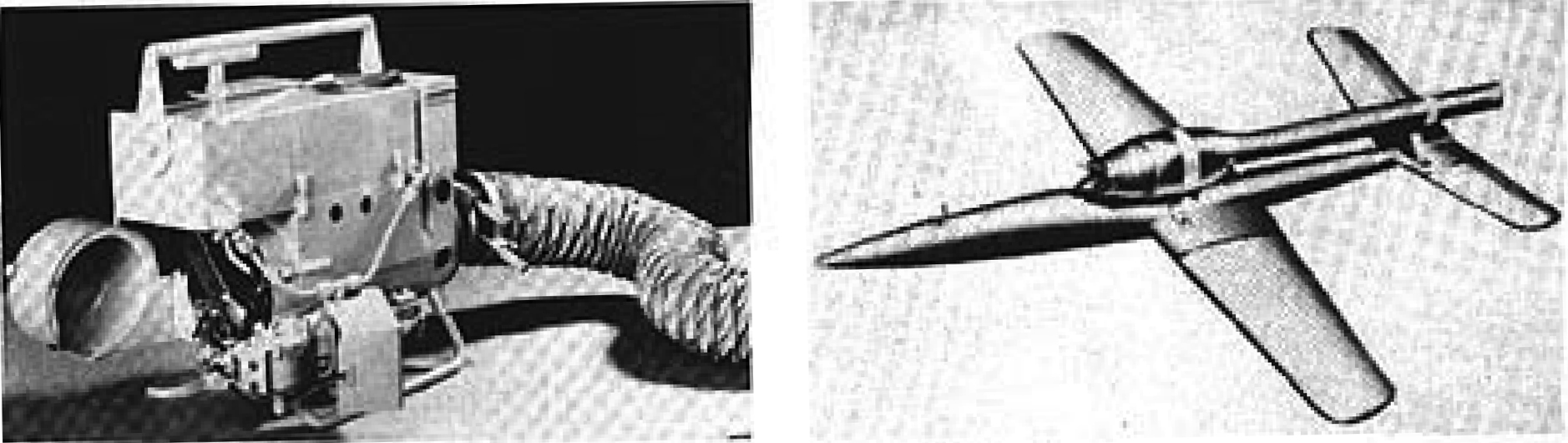

“Smoke-screen generators were developed and produced for the Army and Navy. They used folded pulsejet engines to provide the necessary heat, pressure, and airflow. For commercial markets, an insecticidal fog generator (Dyna-Fog) was produced by the hundreds. It preceded the military generators but operated on the same principles.

“In 1951, the firm was incorporated as the Shevlin Manufacturing Company, that being the maiden name of Bill Tenney’s mother. More people were hired for the purpose of fulfilling, among other things, a new, much larger contract for Army smoke generators. From two people in 1945 to 11 when I was hired in 1949 to a maximum of about 29 in mid-1952, Aeromarine/Shevlin grew as it sought new markets and its reputation became more widely known. During those years, Dyna-Jet sales stabilized at about 100 per month; therefore, they were produced in batches of 1,000 or so only when stocks fell relatively low. Production was then halted until the stock was depleted again.

“While tooling up to manufacture the previously mentioned large quantities of smoke generators for the Army (badly needed during the Korean War), the company learned that the Army’s letter of intent for the contract had been terminated. However, Shevlin was not permitted to bid on a firm contract, apparently due to misunderstandings and ill will among a few principals. Consequently, Shevlin’s blueprints were redrawn by Army personnel and submitted to other manufacturers.

“Even today, it seems very peculiar that Shevlin people were not permitted to see the ‘Army drawings’ because they were ‘classified!’ By a very strange coincidence, the Michigan company which won the contract to produce Shevlin’s designs for the Army was the one which had been previously turned down by Shevlin as a subcontractor on the earlier, aborted agreement. Reportedly, that firm would not guarantee the performance of its components in Shevlin-built generators.

“As evidence that this episode was, at best, borderline illegal in some ways, Bill later won a financial judgement against the Army for its handling of the production order for those smokescreen generators.

“Naturally, Bill was discouraged and disgusted by this sudden and severe loss of business. As a result, he got out of the business completely by selling Shevlin to Russell Curtis of Curtis Automotive Devices (CAD) of Indiana.

“Curtis hired Paul Frank, Aeromarine/Shevlin’s chief engineer, to aid in the transfer of material and technology to Bedford, located in south-central Indiana. Of the eight or so Shevlin people Paul asked to accompany him, three of us did so.

“At CAD, the Dyna-Fog and Dyna-Jet were returned to production after a long delay, and research was begun on smaller versions of both. Additionally, a pulsejet-powered steam generator was being considered. The drafting department was expanded by the hiring of a man who was working on his engineering degree. He was also familiar with the Dyna-Jet, having won many Jet Speed events in previous (and subsequent) years. I refer to James Richmond, currently very active and successful in national and international Indoor Free Flight competition.

“A year-and-a-half after our move to Bedford, only Paul Frank remained, the others of us having left for various reasons. Prototype small Dyna-Fog machines have been fabricated and their refinement begun in preparation for quantity production. However, all other research on pulsejet projects have been halted, including that on the smaller Dyna-Jet. Several years later, ironically, the modestly successful, Japanese-made Tigerjet was placed on sale in this country.

“A few years later, Curtis moved his company to Westfield, located just north of Indianapolis, and changed the company name to Curtis Dyna-Products. Presumably this was an acknowledgement of the renewed importance to his company of the creations and ideas of Aeromarine and Shevlin. It remains so named today, although Mr. Curtis passed away a few years ago.

“I am unaware of all the current products and projects of Curtis Dyna-Products, but I do know of extensive changes in the Dyna-Fog series. Only the Dyna-Jet is the same as years ago. It is probable that improved techniques have been adopted in some production steps, but so far as I can learn, every item in every Dyna-Jet ever produced is interchangeable with its counterpart in any other! Indeed, most of the parts in its foreign clones (at least three of them) are also fully interchangeable—even to their use of US standard threads in a ‘metricized’ country! This, after 40 years of almost continuous production.

“These days, successful competitors in Jet Speed extensively modify their engines. Among other things, they concoct fuel blends, which ‘make a bigger bang’ than does gasoline in this application. It seems safe to say, however, that as manufactured and properly used, the Dyna-Jet remains one of the easiest-starting, most consistent in performance, most reliable, safest, and most economical to operate of any miniature powerplant ever placed in production!”

Once again, I want to thank Gerald L. (Jerry) Wiles for sharing this fascinating bit of personal history with us.

Comments

Add new comment